/%3E1920/iStock-1288551481.jpg?width=500&height=263&name=iStock-1288551481.jpg)

Smart Factory SAP Integration - Factory Kit

Many production companies still work with paper-based production orders and have little transparency about their processes. Missing or outdated production data makes efficient control difficult. This leads to high costs and a slow response to deviations. The Factory Kit supports you on your way to becoming an intelligent and networked company. With the Factory Kit, you can digitalize your production and efficiently implement digital manufacturing with SAP.

-

Optimized production processes

Optimize your manufacturing processes through the vertical exchange of data between ERP and production. This allows you to efficiently control processes in maintenance, quality assurance and production. -

Increased efficiency

Increase the efficiency of your production by recording machine data, reducing unproductive times and flexibly adapting processes.

-

Even better quality management

Increase accuracy in quality management by integrating qualitative and quantitative test results directly into the production process and documenting them in real time.

-

Seamless SAP integration

Facilitate your entry into digital manufacturing with SAP by using an SAP-related solution that connects your production and accelerates digitalization. Experience seamless SAP S/4HANA Public Cloud integration with the Factory Kit.

-

Intelligent processes

Benefit from comprehensive added value by establishing intelligent production processes, making data-based decisions and reacting flexibly to individual requirements.

Factory Kit - For intelligent and SAP-related production

Our Factory Kit solution offers you a simple, SAP-like introduction to intelligent and networked production. The vision of the solution is not based on the individual function, but on a digitized and optimized end-2-end process. Many processes have a core in SAP, which our Factory Kit extends in the direction of production. Exception-based action only works if data from production is available in real time. Functionality and processes are tailored to people and use cases. The Factory Kit provides support on the way to becoming an intelligent and networked company

Added value at all levels

Your company with the smart factory

-

reacts individually to customer requirements

-

makes optimized decisions

-

uses resources productively and efficiently

-

reacts quickly and flexibly to external and internal influences

/%3E1920/iStock-1149529036.jpg?width=500&height=333&name=iStock-1149529036.jpg)

/%3E1920/iStock-1074899602.jpg?width=500&height=333&name=iStock-1074899602.jpg)

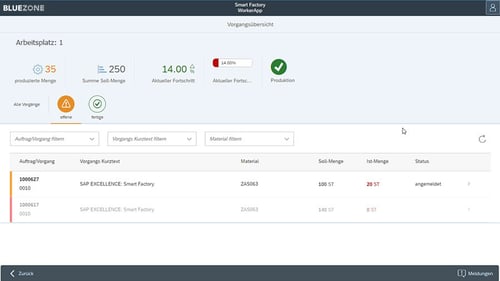

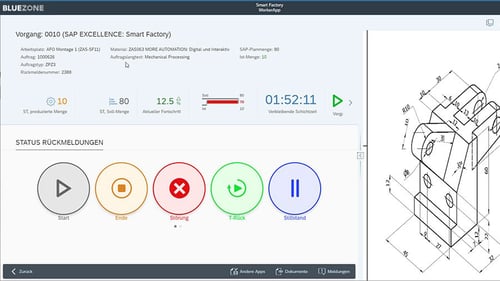

The worker benefits from:

-

Reliable and clear information on clearly structured and simple applications

-

The focus is on the actual workflow - activities from different areas (PP, PM, QM) are made possible in one place

-

Machine takes over data acquisition (automation) or makes suggestions (partial automation)

The foreman/production manager benefits from:

-

Precise recording of the actual situation creates accurate planning requirements in SAP ERP

-

Various evaluations in the SAP standard

-

Ad-hoc target/actual comparisons; ideally situation-based reporting if process is outside the target corridor

-

Central information pool for information from production

-

Clearly defined processes in production that do not require/allow "special logic"

/%3E1920/iStock-1462148857.jpg?width=500&height=281&name=iStock-1462148857.jpg)

/%3E1920/iStock-1059971802.jpg?width=500&height=320&name=iStock-1059971802.jpg)

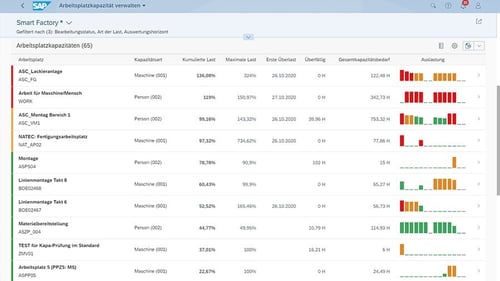

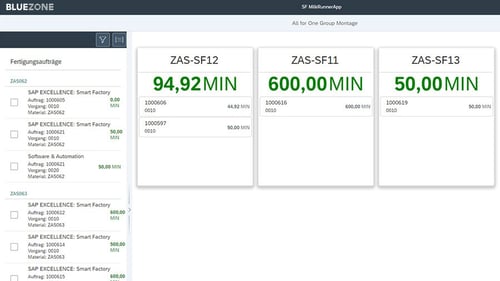

The functions in the smart factory

-

Production planning

- Reduction of manual activities

- Real-time transparency: Which orders are currently running on which machines?

- Increased productivity through direct countermeasures in the event of problems in production (condition monitoring)

- Interactive processes in which machines and products from production trigger processes in SAP

- Optimization of planned and cycle times, as well as rescheduling according to the situation

- Flexible production processes based on currently available capacities and skills

-

Production management

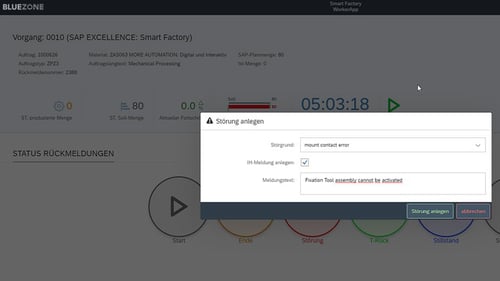

- Precise classification and evaluation of error messages

- Use of machine statuses and workloads for planning and optimization

- Collection and evaluation of IoT data, which can then be used for predictive maintenance scenarios

-

Quality management

- Accurate and time-efficient inspection during production

- Increased accuracy in material and batch traceability

This is the Factory Kit

Process optimization and transparency in production

Our Factory Kit provides up-to-date information on production orders directly to workers or systems. Feedback on times and quantities - manual or automatic - and their analysis provide insights into production processes at all times. This allows unproductive times to be reduced, planning to be adjusted and OEE analyses to be used for continuous optimization.

Fast and adaptive processes in maintenance

The precise, machine-supported recording and classification of faults and downtimes allows simple evaluations of frequencies and complex root cause analyses through to the derivation of models for improved fault prediction. Of course, maintenance messages with relevant information can be created directly in the target system and relevant persons can be informed according to the situation.

Accuracy in quality management

The recording and documentation of qualitative and quantitative inspection results enables integrated inspection during production. The visualization and monitoring of inspection points makes it possible to initiate inspections as required. Depending on the results, follow-up activities are triggered or stopped (e.g. inspection tightening or process interlocks).

Recording and processing machine data

Networked systems and workstations are the central building blocks of a "smart" factory. The Factory Kit enables bidirectional exchange between SAP and machines based on the latest standards - and thus drives Industry 4.0 at the automation level. Vertical data integration creates store floor-integrated end-to-end processes and analyses. A particular highlight is the event-based process control, which enables highly dynamic processes.